With over two decades of expertise, Sanjana HandiCrafts specializes in delivering exceptional-quality jewelry with precision, timely delivery, and unmatched customer support. Powered by cutting-edge German technology and state-of-the-art machinery, our operations are driven by a dedicated workforce of 2,500+ skilled team members and a robust production capacity of 125,000+ pieces per month — ensuring excellence at every step.

Explore, how we can help you!

Customized Manual Design (OEM/ODM)

Our in-house team of expert designers excels in both manual sketching and advanced 3D software, offering fully tailored OEM and ODM solutions with precision and creativity.

3D Prototyping

We bring your ideas to life faster with high-precision 3D prototyping using cutting-edge printers from 3D Systems, USA — the global leader in 3D printing technology.

Casting

Our casting process combines safety and precision, using Schultheiss (Germany) technology and Yasui (Japan) wax injectors to ensure flawless, high-quality results every time.

Disc Finishing

For superior metal finishing, we use advanced Disc Finishers by Avalon (Poland) and PMG Electro & Polishing machines from Hispana (Spain) to ensure a flawless, high-gloss surface.

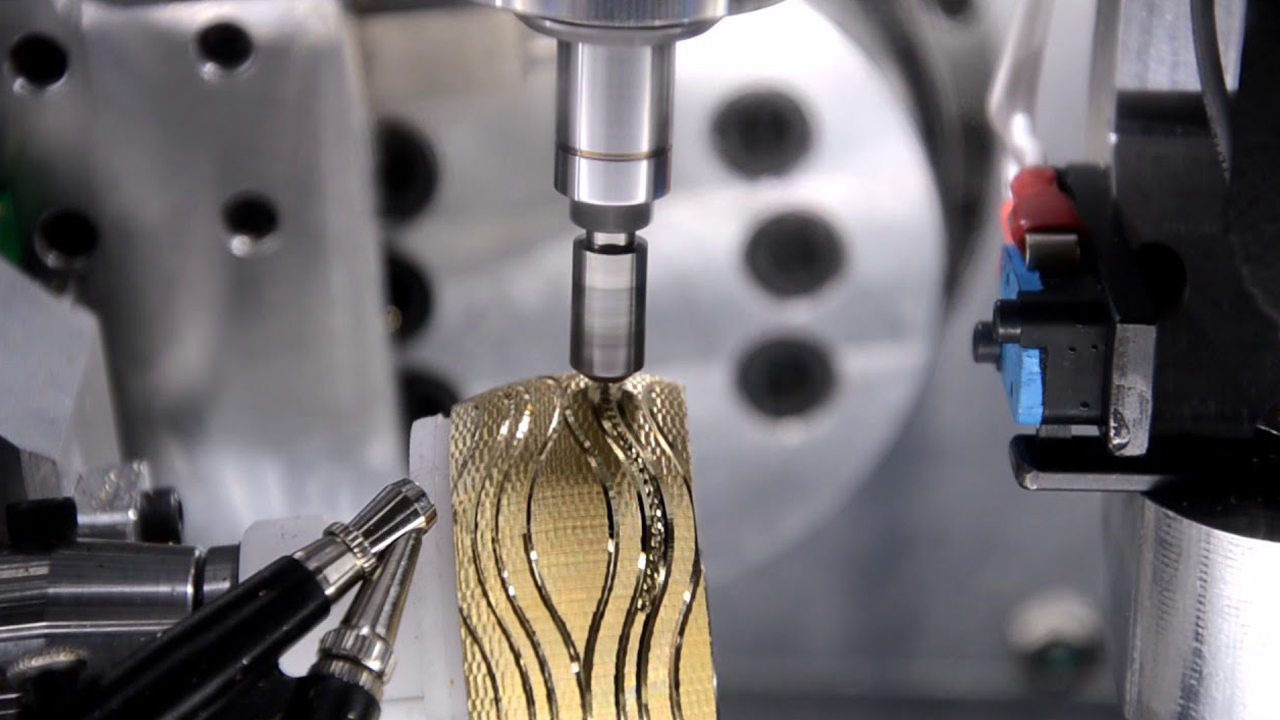

CNC

We use advanced 4-axis CNC Routers by Intech to craft highly intricate designs with unmatched accuracy — perfect for pieces too complex to make by hand.

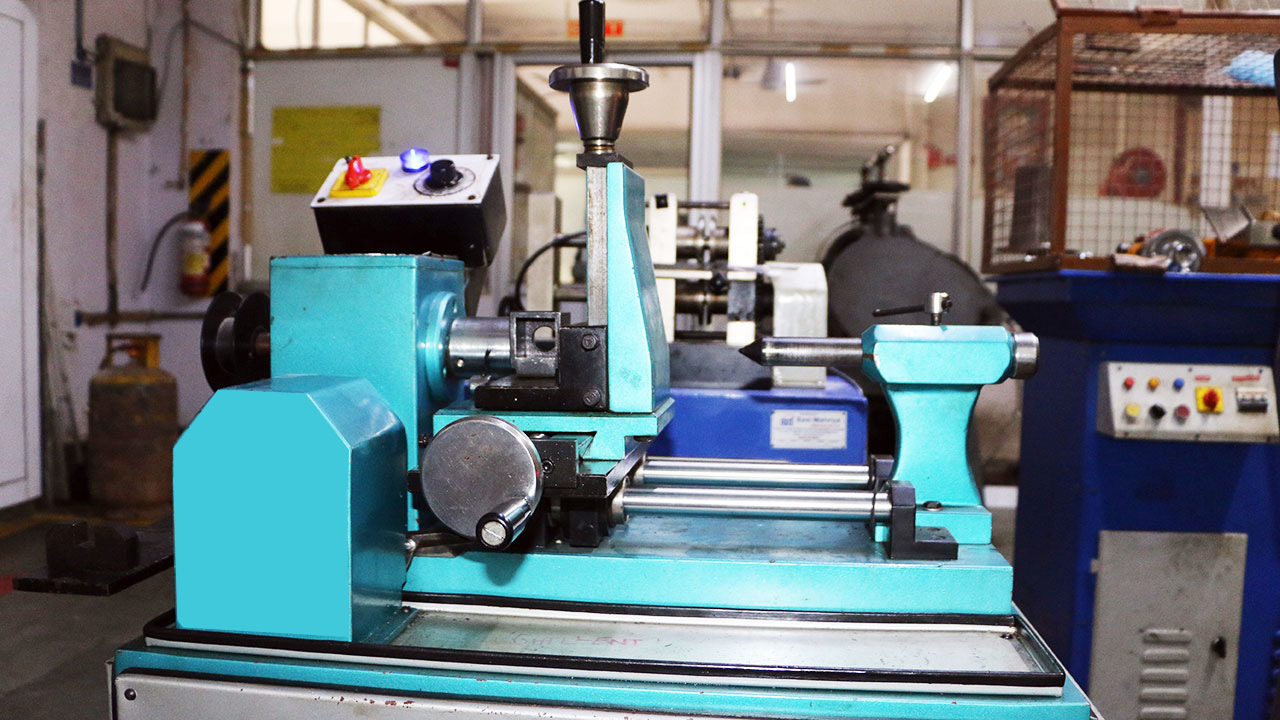

Continuous Casting

Our advanced continuous casting technology ensures smoother metal surfaces, reduced deburring, and greater wear resistance for findings, wires, and tubes.

Hollow Tubing

Our advanced infrastructure allows us to create complex geometric tubing shapes — including square, round, and hexagonal — for even the most technically demanding jewelry designs.

Hardening Furnace

Our hardening furnace enhances durability and workability of complex findings by creating a soft core and latent compressive stress — ensuring strength without compromising precision.

Laser Soldering

We use state-of-the-art laser soldering equipment from Siro Lasertec and Rofin (Germany) for ultra-precise, safe, and clean soldering of delicate jewelry components.

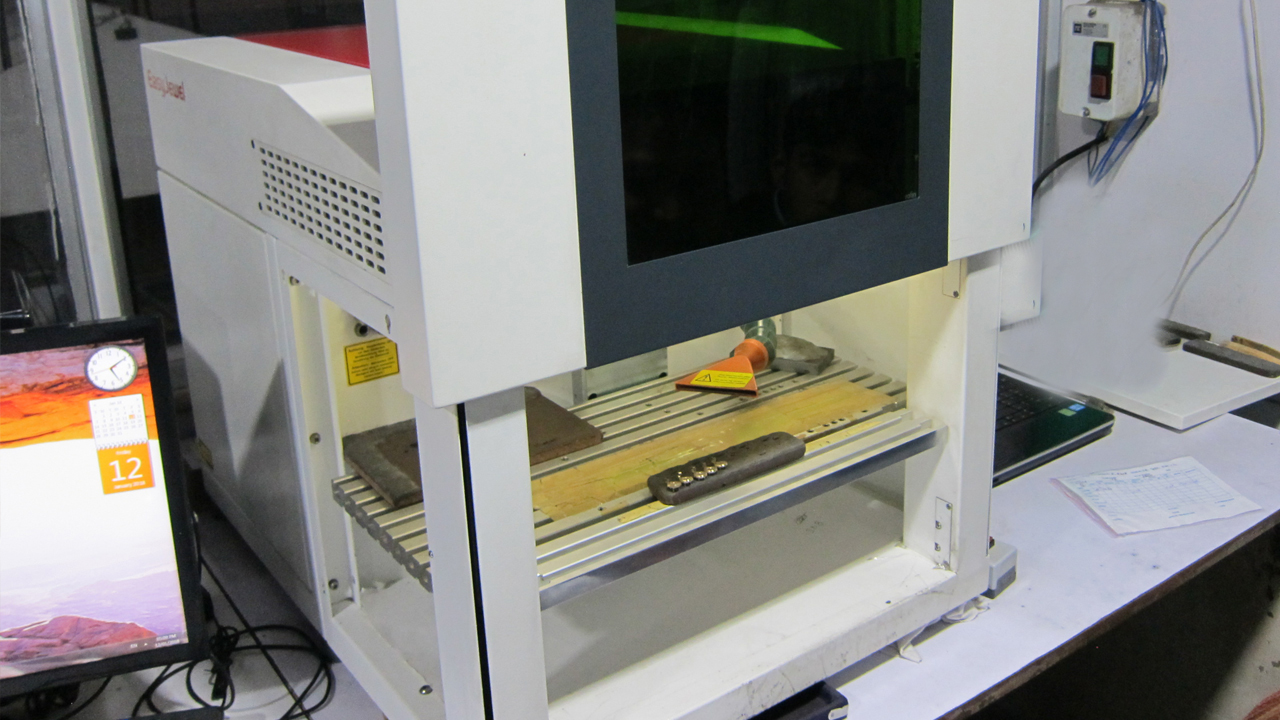

Laser Marking

We ensure sharp, detailed hallmarking and branding using top-tier laser marking machines from Sisma (Italy) and Rofin (Germany) for lasting precision.

Plating / Micron Plating

We achieve exceptional consistency and precision in plating using Walter Lehmann baths (Germany), with high-quality solutions from Pino Aliprandini (Switzerland) and Umicore (Germany).

Assaying / X-Ray

We use Fischer (Switzerland) technology for precise material analysis, micron coating thickness, and micro-hardness testing. Every micron-plated piece is mandatorily verified for quality and accuracy.